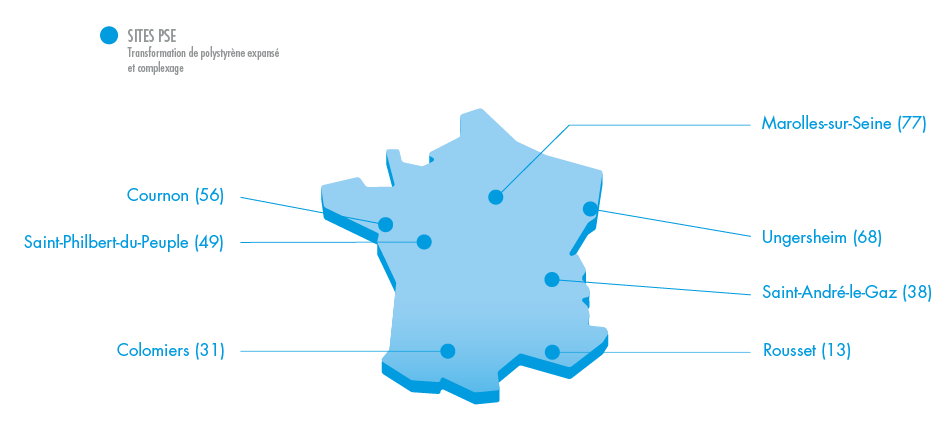

Knauf Bâtiment has been processing polystyrene for over 30 years in France and has outstanding expertise in this material, particularly via its dedicated Research and Development Centre in Ungersheim (68 – France). With 7 regional EPS processing sites, Knauf supplies its customers closer to their worksites.

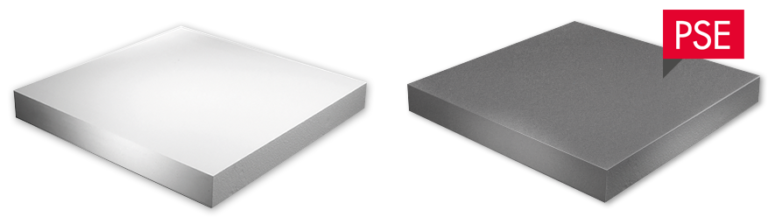

Its offering is comprehensive, high-performance and economical, and is the gold standard in terms of building envelope insulation solutions, with two expanded polystyrene ranges: Knauf Therm, a white EPS, and Knauf XTherm, a grey EPS with superior insulating properties.

In 2021, Knauf innovates and launches NexTherm®, a new generation of very low carbon EPS from renewable resources.

As such, whatever the design choice, Knauf offers a tailored and certified EPS solution for building envelope insulation:

and as lightweight backfill material for both landscaping features and engineering structures, with the Geofoam TP brand.

Isobox Isolation, the specialiste xpanded polystyrene thermal insulation brand for over 50 years, joined the Knauf group in 2014.

Affiliated with Knauf Industries, it is supported by a national network served by 19 plants in France for its production.

ISOBOX Isolation provides solutions to ensure easier construction, improve comfort and promote energy savings.

Its experience makes it a preferential partner, capable of handling bespoke projects for industrial firms in the construction sector and designing in conjunction with its clients, technical parts or insulation material offering a combination of quality, thermal performance and easy use.

It is particularly involved in the flooring, swimming pool, construction, and underfloor heating sectors.

ISOBOX Isolation also makes use of expert industrial know-how to develop standard expanded polystyrene insulating materials, intended for various applications in both new and renovation projects:

ISOBOX Isolation is also characterised by its capacity for innovation, through the technological know-how and performance of its research and development departments.

An ID Lab, dedicated to innovation, works in the following areas:

Isobox Isolation has joined the other members of the Knauf group: Knauf Bâtiment and Knauf Industries in the Knauf Circular® process, to make its eco-responsible action a reality and meet its customers’ needs.

In construction:

Knauf and Isobox Isolation are members of the French Association of Expanded Polystyrene Insulating Materials in the Construction Sector (AFIPEB), a network committed to construction waste recycling.

As early as 2012, fully aware of the challenges in respect of the circular economy, expanded polystyrene (EPS) insulating material manufacturers signed a waste management charter for their products. In 2019, they initiated an additional process to promote recycling, by signing a voluntary commitment with an ambitious goal: to recycle 2500 tonnes of EPS insulating materials in 2025.

Find out more about Knauf Industries’ activity, the packaging division and technical parts from the Knauf group

Find out more