Expanded polystyrene is a cellular plastic material, composed of 98% air and 2% of a refinery by-product, naphtha, that is not reusable as fuel, or more recently bio-naphtha, made from renewable resources (biomass from organic or forestry waste).

More and more EPS products contain recycled polystyrene.

Due to its multiple properties, it is an outstanding material: it is an excellent thermal and thermo-acoustic insulator, it offers high compressive strength properties, it is shock-absorbent, water-repellent, lightweight, suitable for food contact, stable, and retains all its properties over time.

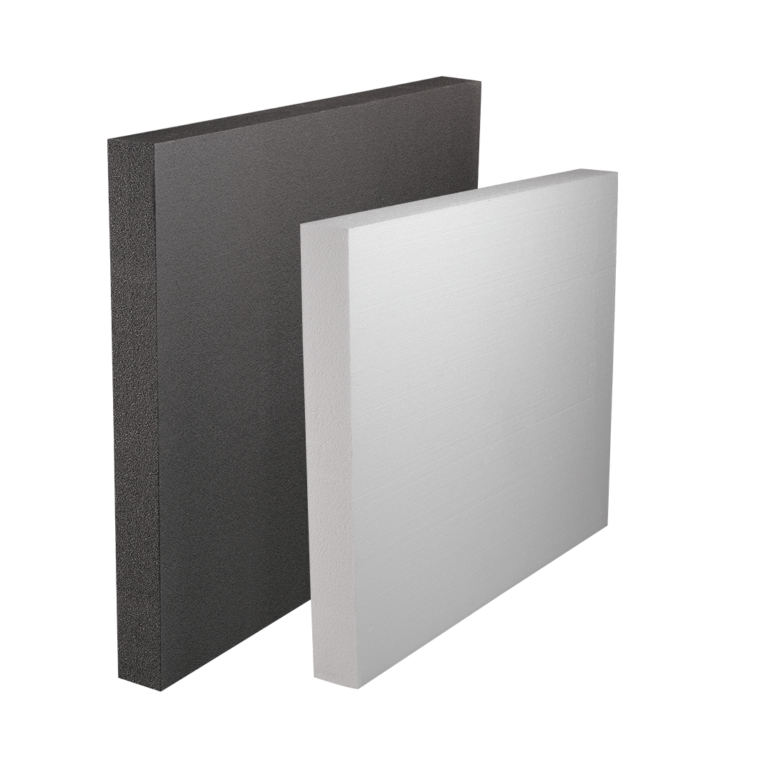

There are several types of polystyrene, white EPS and grey (or graphite) EPS. The latter owes its colour to the addition of graphite or other carbon derivatives to white polystyrene, enhancing the thermal and acoustic insulation properties.

EPS can also be coloured by adding coloured EPS beads (blue for Knauf, orange for Isobox Isolation) or by colouring the material (blue colour for seafood packaging, for example).

EPS is primarily used in the construction sectors, as an insulating material or lightweight backfill material, and in the agri-food and industrial sectors, as isothermal and/or protective packaging materials or as technical parts.

EPS panels insulate all the walls of the building envelope: internal walls, frontages, flat and inclined roofing, flooring, flagstone soffits, etc. In a lesser-known use, EPS blocks form lightweight backfill material for engineering structures and landscaping features. EPS also forms formwork blocks for home building and swimming pools.

EPS packaging materials are used for shipping and protecting foodstuffs (seafood, meat, fruit and vegetables) and heat-sensitive products (vaccines, medication).

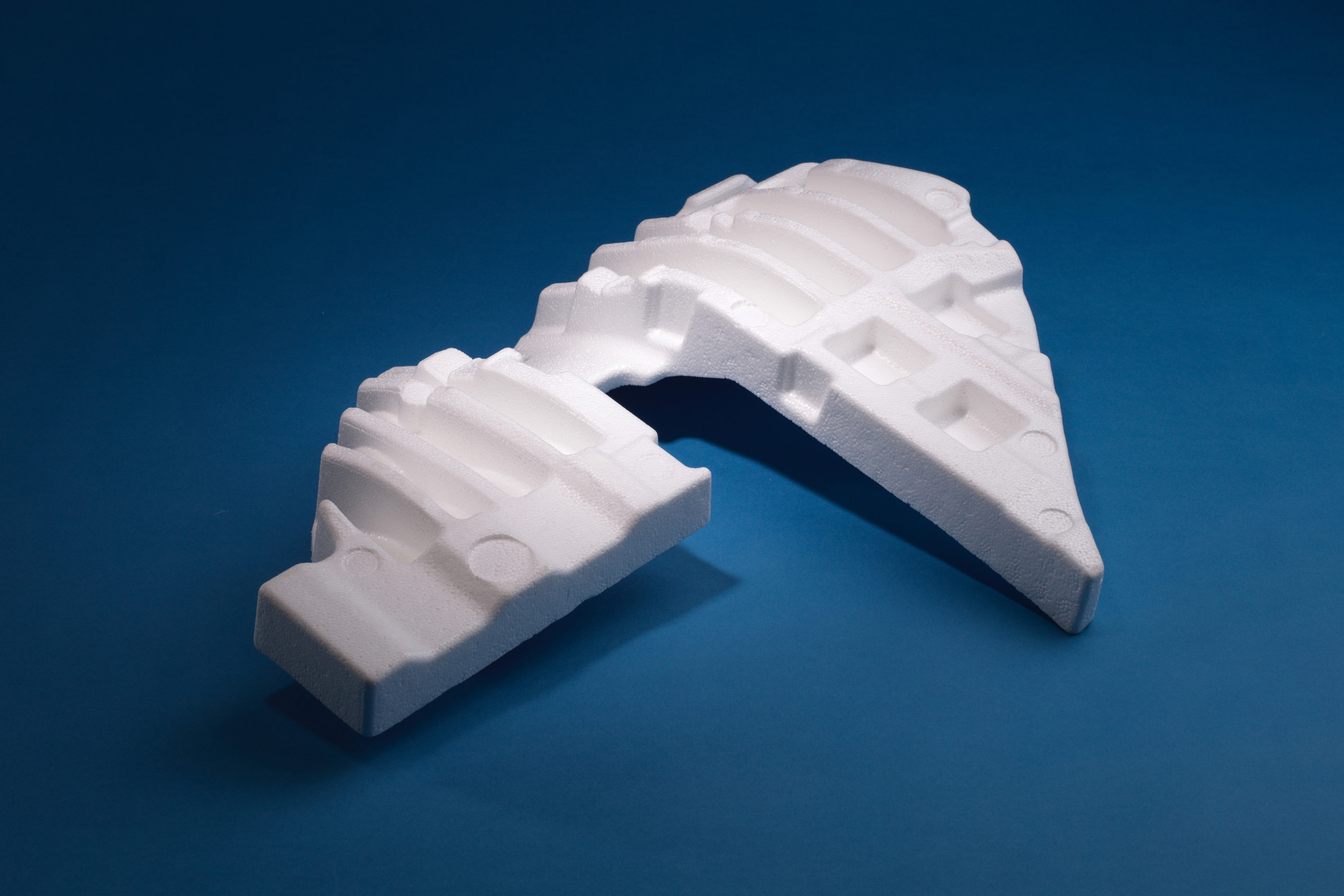

Expanded polystyrene (EPS) is used for producing both packaging materials and protective fillers.

Finally, it is used for producing technical parts for various industries such as the automotive industry and joinery.

All EPS production waste as well as worksite waste is ground and reintroduced into the manufacture of new EPS products (subject to certain conditions).

The proportion of recycled material in the new product is dependent on the characteristics of the end product, in particular the expected mechanical and fire properties. The recycling and recovery of EPS from deconstruction, still representing a small volume to date, will become accessible to businesses in the years to come through the set-up of reprocessing plants in Europe.

Life cycle